How much do you know about the external electroplating evaporation aluminum process of candlestick&#

- Author:Demi

- Source:Sunny Glassware

- Release Date:2022-08-01

Sunny Group has offered glassware since 1992 with all kinds of products being exported to more than 30 countries and regions.We all know the diversity of candlestick process, so how much do you know about the external electroplating evaporation process of candlestick? Next let Sunny glassware take you to understand: the external electroplating evaporation aluminum process of candlestick.

Plating time and plating quantity: normal plating time pendant + plating in 15-20 minutes a furnace; Regular 88100.8090 cups of these sizes are plated around 250-280 per stove

Light cup requirements: direct external plating of the light cup requirements are relatively high, but due to the production of light cup, the surface of the light cup often appear scratches, pitting, clip printing and other phenomena, especially the light cup is especially obvious, so this process will require the injection of bottom oil replating;

Prone to problems: but spray bottom oil replating if the process is not good, it is also easy to appear other problems, such as (spray paint color, spray paint foaming, surface pitting, rubbing, electroplating Yin and Yang surface, electroplating yellowing and some other problems).

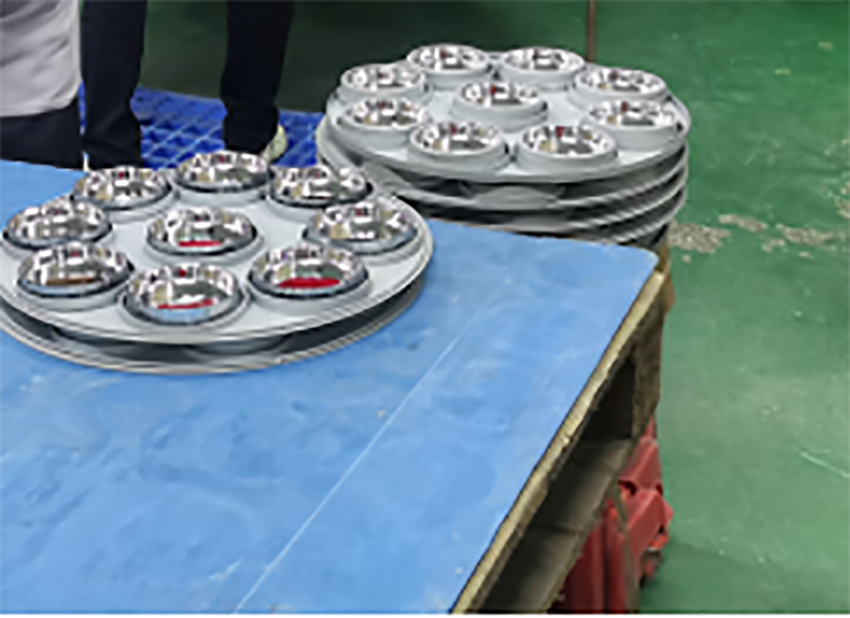

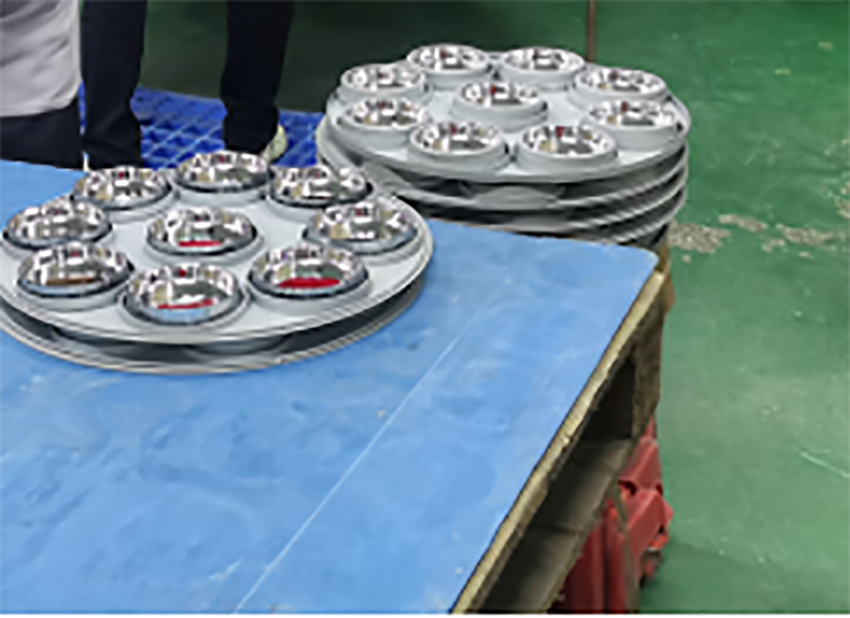

Hang way: conventional products often plating method is a single rod multi-layer multiple 360 rotary plating; If it is a large product or the effect of plating gradient will be a single rod multi-layer, single plating.

Outer plating machine inner plating: This practice is created in the factory in the first column, the plating method is suitable for the product is only the large caliber high moderate (e.g., the great circle cylinder), 15-25 mm high basic unlimited, lid is at present the company a lot of products can be used within the degree of machine do plating (such as compiling lines cover, diamond cover, cover stitch, chrysanthemum series cover, etc.), it greatly improve the electroplating production, With the outer plating machine plating inside the need to do the corresponding occlusion fixture.

Evaporation of aluminum inside and outside silver plating is currently this process in the south. The north is very mature, the quality of plating is good, the output is not high mainly depends on the operation of the factory, the following describes the nature of the process and some easy problems:

Process formation: tungsten wire + aluminum wire

Plating time and plating quantity: normal plating time pendant + plating in 15-20 minutes a furnace; Regular 88100.8090 cups of these sizes are plated around 250-280 per stove

Light cup requirements: direct external plating of the light cup requirements are relatively high, but due to the production of light cup, the surface of the light cup often appear scratches, pitting, clip printing and other phenomena, especially the light cup is especially obvious, so this process will require the injection of bottom oil replating;

Prone to problems: but spray bottom oil replating if the process is not good, it is also easy to appear other problems, such as (spray paint color, spray paint foaming, surface pitting, rubbing, electroplating Yin and Yang surface, electroplating yellowing and some other problems).

Hang way: conventional products often plating method is a single rod multi-layer multiple 360 rotary plating; If it is a large product or the effect of plating gradient will be a single rod multi-layer, single plating.

Outer plating machine inner plating: This practice is created in the factory in the first column, the plating method is suitable for the product is only the large caliber high moderate (e.g., the great circle cylinder), 15-25 mm high basic unlimited, lid is at present the company a lot of products can be used within the degree of machine do plating (such as compiling lines cover, diamond cover, cover stitch, chrysanthemum series cover, etc.), it greatly improve the electroplating production, With the outer plating machine plating inside the need to do the corresponding occlusion fixture.