10 Days to Overcome the "Glass Embroidery" Challenge! Sunny Glassware Secures $2 Million O

- Author:Demi

- Source:Sunny Glassware

- Release Date:2025-09-19

At 11 p.m., Sunny Glassware received a new email notification. The sender was Anderson, the procurement director of a high-end homeware brand in California, USA. The email read: "While searching for borosilicate glass cup suppliers on Google, your company’s innovative craftsmanship case caught our attention. We urgently need to customize a batch of artistic borosilicate glass cups. Attached are the design drafts, and we look forward to collaborating."

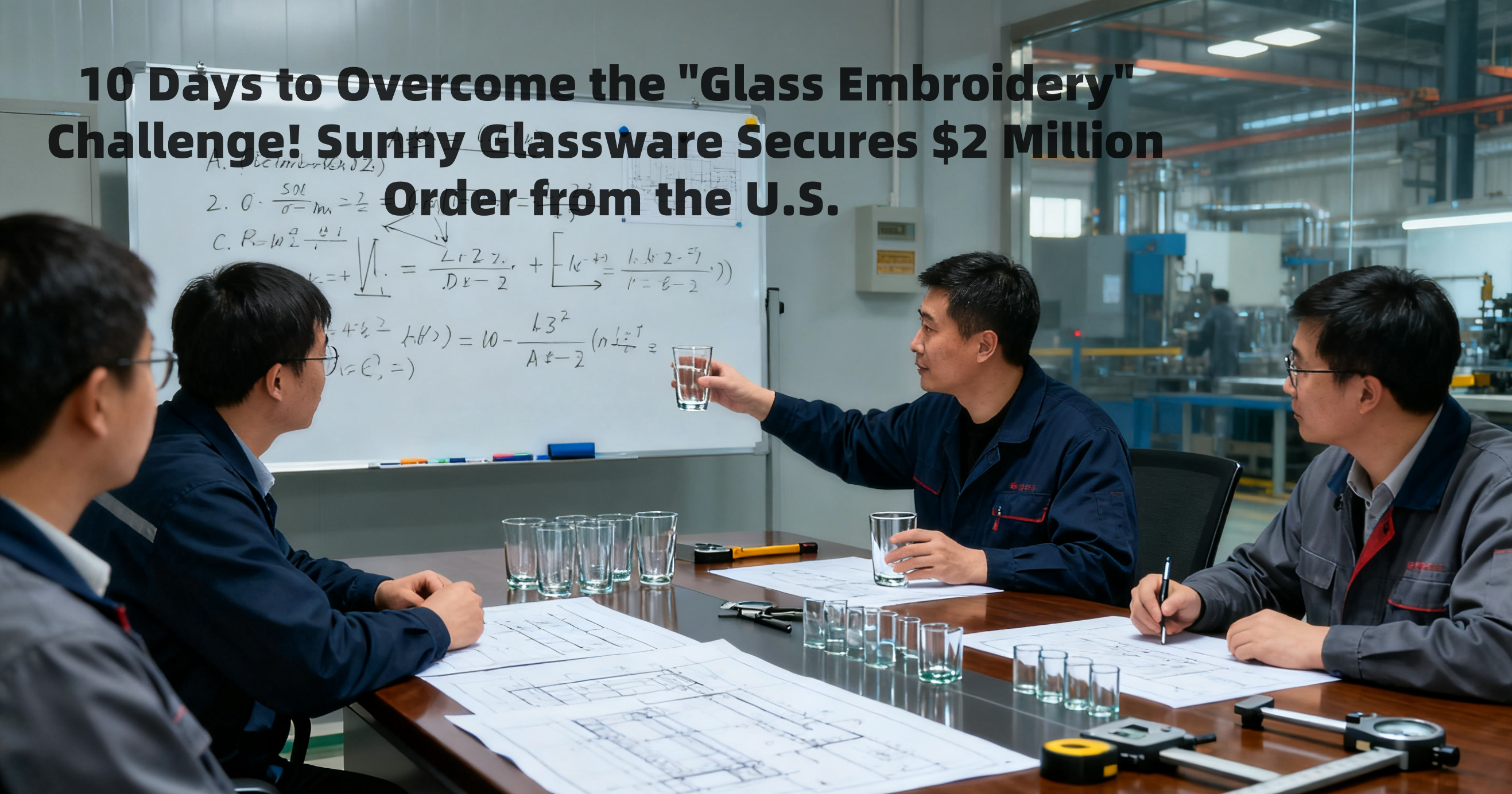

Opening the attachment, the exquisite design revealed a unique challenge—the cup body featured a double-layer hollowed-out floral pattern, with gold foil embedded in the inner layer, and it needed to withstand temperature changes from -20°C to 120°C. Early the next morning, Sunny Glassware immediately convened aconference. Factory master Zhou frowned and said, "The hollowed-out floral pattern requires precise control of the glass flow rate during high-temperature molding. Embedding gold foil is even more challenging, as it may lose its luster due to high-temperature oxidation. This is as difficult as embroidering on glass."

But the team did not back down. The design team first used 3D modeling to simulate the product structure, adjusting the density of the hollowed-out patterns to ensure strength. The factory experimented with replacing gold foil with a special alloy sheet and developed a "low-temperature segmented embedding method" to complete the decoration when the glass was semi-solidified. To address the temperature change issue, engineers spent two weeks in the lab, adjusting the raw material formula 13 times, and finally found the optimal trace element ratio.

However, new issues arose during trial production. The first batch of samples developed fine cracks in the hollowed-out sections, with a pass rate of less than 30%. Sunny and the team worked day and night to analyze the problem and discovered it was caused by uneven heat dissipation in the mold. They urgently contacted the mold supplier, used new thermally conductive materials to remake the mold, and added infrared thermal imaging monitoring during the blowing process to adjust the temperature in real time.

After 10 days of repeatedly adjusting and fine-tuning, when thetranslucent glass cup samples were presented to Anderson, the rigorous procurement director broke into a surprised smile. "This completely exceeds our expectations!" Anderson exclaimed excitedly during a video conference. "Especially the integration of gold foil and glass, which combines artistry with practicality."

In the end, Sunny Glassware successfully secured the $2 million order. On the day of delivery, Anderson sent a video message: "These cups were a huge success at the Los Angeles Exhibition, and many clients inquired about the manufacturer. We look forward to establishing a long-term partnership with Sunny Glassware!" From a Google search to order fulfillment, this cross-Pacific collaboration is not only a victory for Sunny Glassware technical capabilities but also a vivid portrayal of the craftsmanship spirit of Chinese manufacturing.